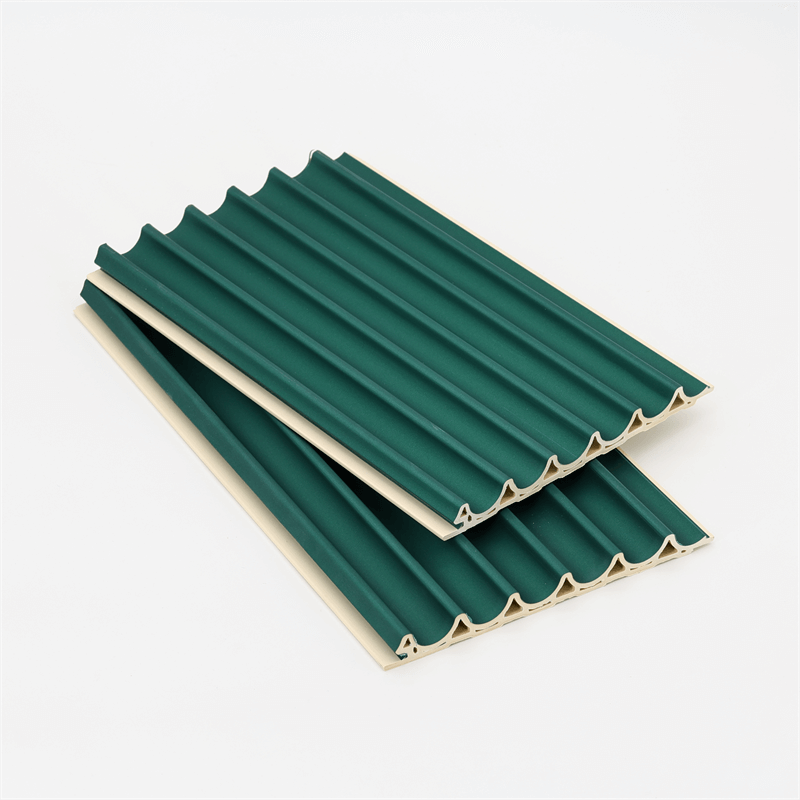

Wood Plastic Composite (WPC) fluted panels have gained popularity as a sustainable and durable building material with a wide range of applications.

To ensure their long-lasting performance and aesthetics, proper installation and regular maintenance are essential. In this article,

we will provide a comprehensive guide on the installation and maintenance of WPC fluted panels,

offering valuable tips to help you maximize the benefits of this innovative material.

Preparing for Installation

Before embarking on the installation process, it is crucial to undertake essential preparatory steps to ensure a successful outcome:

Inspect the Panels: Thoroughly inspect the WPC fluted panels upon delivery to check for any visible defects, damages, or discrepancies in color and finish.

Address any concerns with the supplier or manufacturer before commencing the installation.

Acclimatize the Panels: Allow the panels to acclimate to the installation environment for at least 48 hours before the actual installation.

This step ensures that the panels adjust to the temperature and humidity of the surroundings, minimizing the risk of dimensional changes after installation.

Prepare the Substrate: Ensure that the substrate surface, whether it’s a wall, ceiling, or framing, is clean, dry, and free from any debris or irregularities.

A smooth and level substrate provides a solid foundation for the WPC fluted panels, promoting stability and adherence.

Installation Guidelines

The installation process of WPC fluted panels requires careful attention to detail and precision.

Follow these guidelines for a smooth and successful installation:

Use Proper Tools: Utilize the appropriate tools for cutting, drilling, and fastening the WPC fluted panels.

Ensure that the cutting tools have fine-toothed blades to minimize chipping and splintering.

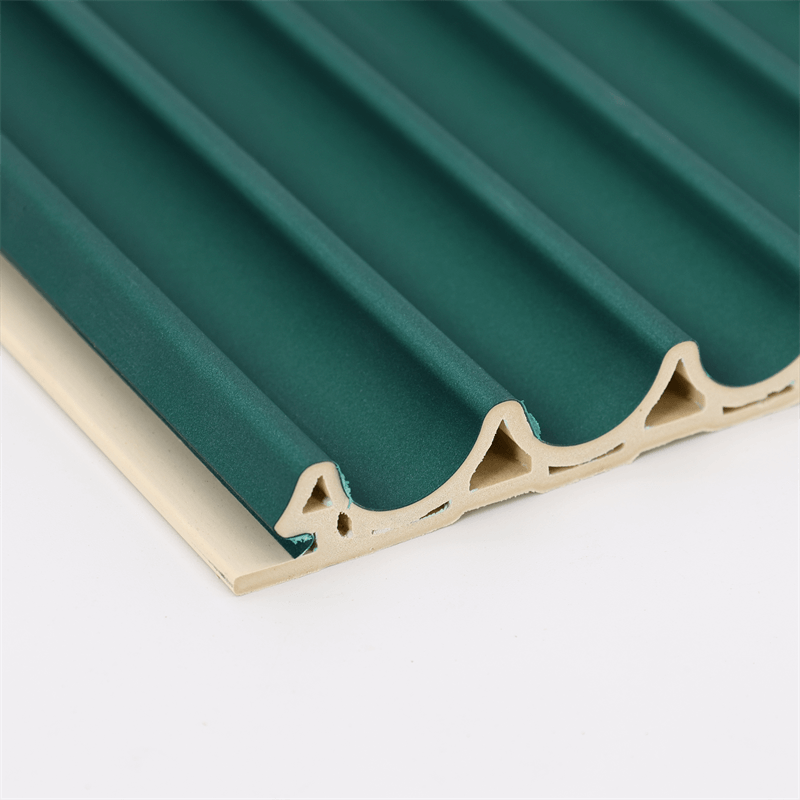

Create Expansion Gaps: Leave a small expansion gap of approximately 3-5 mm between the edges of the WPC fluted panels and adjacent surfaces, such as walls or other panels.

This gap accommodates any potential expansion or contraction due to temperature and humidity changes.

Avoid Direct Contact with Metals: Avoid direct contact between WPC fluted panels and metal materials, as this can lead to discoloration or corrosion over time.

Use appropriate isolation materials or gaskets when necessary.

Interlock Panels Securely: If the WPC fluted panels feature an interlocking system,

ensure that the panels are interlocked securely to create a seamless and uniform appearance.

Apply Proper Fasteners: Use recommended fasteners designed for WPC fluted panels to ensure secure and stable installation.

Avoid over-tightening the fasteners, as it may cause damage to the panels.

Follow Manufacturer Instructions: Adhere to the specific installation guidelines provided by the manufacturer.

Different brands or types of WPC fluted panels may have unique requirements for installation.

Regular Maintenance

Maintaining WPC fluted panels properly is essential to preserve their appearance and performance over time.

Here are some maintenance tips to keep your WPC fluted panels looking their best:

Cleaning: Regularly clean the panels with a soft-bristled brush or a damp cloth to remove dust, dirt, and any surface stains.

For stubborn stains, use a mild detergent mixed with water. Avoid abrasive cleaners or harsh chemicals that may damage the panels.

Avoid Heat Exposure: While WPC fluted panels are resistant to temperature changes,

it is advisable to avoid placing hot objects directly on the panels, as extreme heat can cause warping or discoloration.

Prevent Scratches: Take care to prevent scratches on the surface of the panels.

Use soft pads or felt protectors under furniture legs and avoid dragging heavy objects across the panels.

Inspect for Damage: Regularly inspect the WPC fluted panels for any signs of damage, such as cracks, chips, or loose fasteners.

Address any issues promptly to prevent further deterioration.

Seal and Refinish: If your WPC fluted panels have a wood-like appearance,

you may consider applying a clear sealant or finish to enhance their longevity and protect them from UV exposure.

Addressing Common Issues

Even with proper installation and maintenance, some common issues may arise over time.

Here are some troubleshooting tips to address these concerns:

Fading: If the panels show signs of fading due to UV exposure, consider applying a UV-resistant sealant or finish to protect them from further damage.

Mold and Mildew: In damp or humid environments, mold and mildew may develop on the panels’ surface.

Clean the affected areas with a mixture of water and mildew cleaner, and ensure proper ventilation to prevent future growth.

Surface Stains: Address surface stains promptly using a mild detergent and water mixture.

Avoid using abrasive pads or harsh chemicals, as they may damage the panels’ surface.

Loose Fasteners: If you notice loose fasteners or screws, tighten them carefully to secure the panels back in place.

Replace any damaged fasteners as needed.

By following the proper installation guidelines and regular maintenance tips outlined in this guide,

you can ensure the long-lasting performance and aesthetics of WPC fluted panels.

These innovative and eco-friendly materials offer an excellent solution for a wide range of interior and exterior applications,

providing durability, sustainability, and visual appeal to enhance any space.

With proper care and attention, WPC fluted panels can serve as a valuable investment, contributing to a greener and more aesthetically pleasing environment.