In an era where environmental sustainability is at the forefront of global concerns,

the construction industry is actively seeking eco-friendly alternatives to traditional building materials.

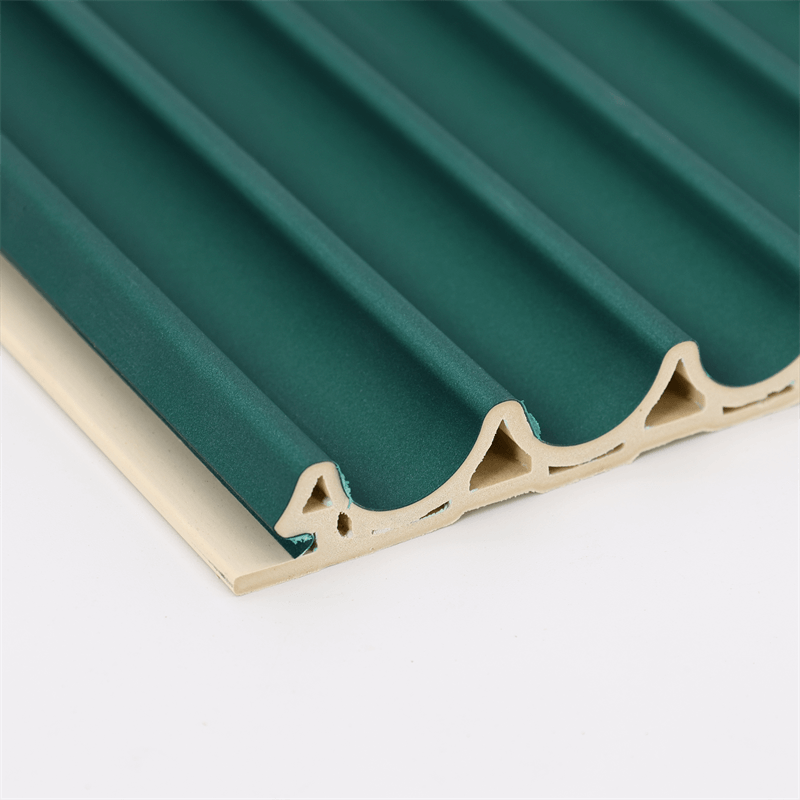

Wood Plastic Composite (WPC) fluted panels have emerged as a leading sustainable building solution, offering a myriad of advantages that align with green building principles.

In this article, we will explore the eco-friendly benefits of WPC fluted panels, delving into their renewable sourcing, low carbon footprint, recyclability, and positive impact on indoor air quality.

Renewable Sourcing: Harnessing the Power of Recycled Materials

WPC fluted panels stand as a testament to the concept of circular economy, which promotes the reuse and recycling of materials to minimize waste and resource depletion.

One of the most significant eco-friendly advantages of WPC fluted panels lies in their sourcing of recycled materials:

Recycled Wood Fibers: These panels incorporate reclaimed wood fibers, sourced from post-consumer wood waste or byproducts of the lumber industry.

By utilizing recycled wood, the demand for virgin timber is reduced, lessening the pressure on natural forests and promoting responsible forest management.

Post-Consumer Plastics: WPC fluted panels also integrate post-consumer plastic waste, such as recycled HDPE (High-Density Polyethylene) or other plastics.

Diverting plastic waste from landfills and oceans helps address the pressing issue of plastic pollution, minimizing environmental harm.

The combined use of recycled wood and plastic materials not only reduces waste but also conserves energy that would otherwise be required in the production of virgin materials.

By embracing renewable sourcing, WPC fluted panels play a vital role in promoting sustainability and minimizing environmental impact.

Low Carbon Footprint: Embracing Energy-Efficient Manufacturing

Traditional construction materials often involve energy-intensive processes, leading to higher carbon emissions.

WPC fluted panels present an eco-friendly alternative with their low carbon footprint, primarily due to the energy-efficient manufacturing process:

Reduced Energy Consumption: The production of WPC fluted panels requires significantly less energy compared to conventional building materials like cement, steel, or aluminum.

The use of recycled materials contributes to this efficiency, as the energy-intensive processes associated with extracting and processing raw materials are minimized.

Energy from Renewable Sources: Manufacturers are increasingly adopting renewable energy sources, such as solar or wind power, to power their production facilities.

This shift towards sustainable energy further reduces the carbon footprint of WPC fluted panels and enhances their overall eco-friendliness.

By opting for low-carbon building materials like WPC fluted panels, the construction industry can take substantial strides towards mitigating the impact of climate change and moving towards a more sustainable future.

Recyclability: Closing the Loop in Construction

Sustainability encompasses not only the sourcing and manufacturing of materials but also their end-of-life impact.

WPC fluted panels excel in this aspect, as they are recyclable and contribute to the circularity of materials in the construction industry:

Biodegradability: At the end of their life cycle, WPC fluted panels are biodegradable, breaking down naturally over time.

This characteristic ensures that the panels do not persist in landfills or contribute to environmental pollution.

Recycling Capabilities: Recycling facilities can process discarded WPC fluted panels to reclaim their constituent materials.

These recycled materials can then be incorporated into new panels or other products, extending their useful life and reducing the need for virgin resources.

The recyclability of WPC fluted panels aligns with the growing emphasis on waste reduction and resource conservation,

making them a sustainable choice for builders and designers looking to close the loop in the construction industry.

Enhancing Indoor Air Quality: A Healthier Living Environment

Apart from their positive impact on the external environment, WPC fluted panels also contribute to creating a healthier indoor living environment for occupants.

This advantage is particularly significant as indoor air quality can have a profound impact on human health and well-being:

Low Emission of VOCs: Volatile Organic Compounds (VOCs) are harmful chemicals emitted by some building materials, furnishings, and cleaning products, contributing to indoor air pollution.

WPC fluted panels have low or no VOC emissions, ensuring that they do not compromise indoor air quality or pose health risks to occupants.

Resistance to Mold and Mildew: WPC fluted panels have inherent resistance to moisture, preventing the growth of mold and mildew.

This characteristic helps maintain a healthy indoor environment, particularly in areas prone to high humidity or moisture, such as bathrooms and kitchens.

Allergen-Free: Unlike certain materials that can harbor allergens and dust particles,

WPC fluted panels are easy to clean and maintain, reducing the likelihood of allergen buildup and improving overall indoor air quality.

WPC fluted panels present a compelling case for sustainable building solutions, showcasing their eco-friendly

advantages in renewable sourcing, low carbon footprint, recyclability, and positive impact on indoor air quality.

As the construction industry continues to embrace green building practices,

WPC fluted panels offer a viable and responsible choice for architects, builders, and designers aiming to create sustainable and healthy living spaces.

By harnessing the power of recycled materials and promoting circularity, WPC fluted panels exemplify the possibilities of a greener and more sustainable future for construction and design.